- Intelligent and economical: Thanks to pioneering technologies in body-in-white construction and drive architecture, the Aiways U5 SUV weighs 350kg less in comparison its competitors

- Unrivaled light weight and durability: Advanced recuperative braking system and low vehicle weight ensure long service life of chassis components

- Cost-effective and sustainable: 100,000km service interval ensures low maintenance costs

Shanghai/Munich, August 24, 2022 – Battery-electric vehicles score with lower operating costs compared with conventionally powered ones. In developing the U5 SUV, Aiways placed particular focus on intelligent lightweight construction, an efficient powertrain and the best possible thermal management of the battery to keep energy requirements as low as possible. But the result not only pays off at the charging station, but also in generally lower maintenance costs thanks to a 100,000km service interval.

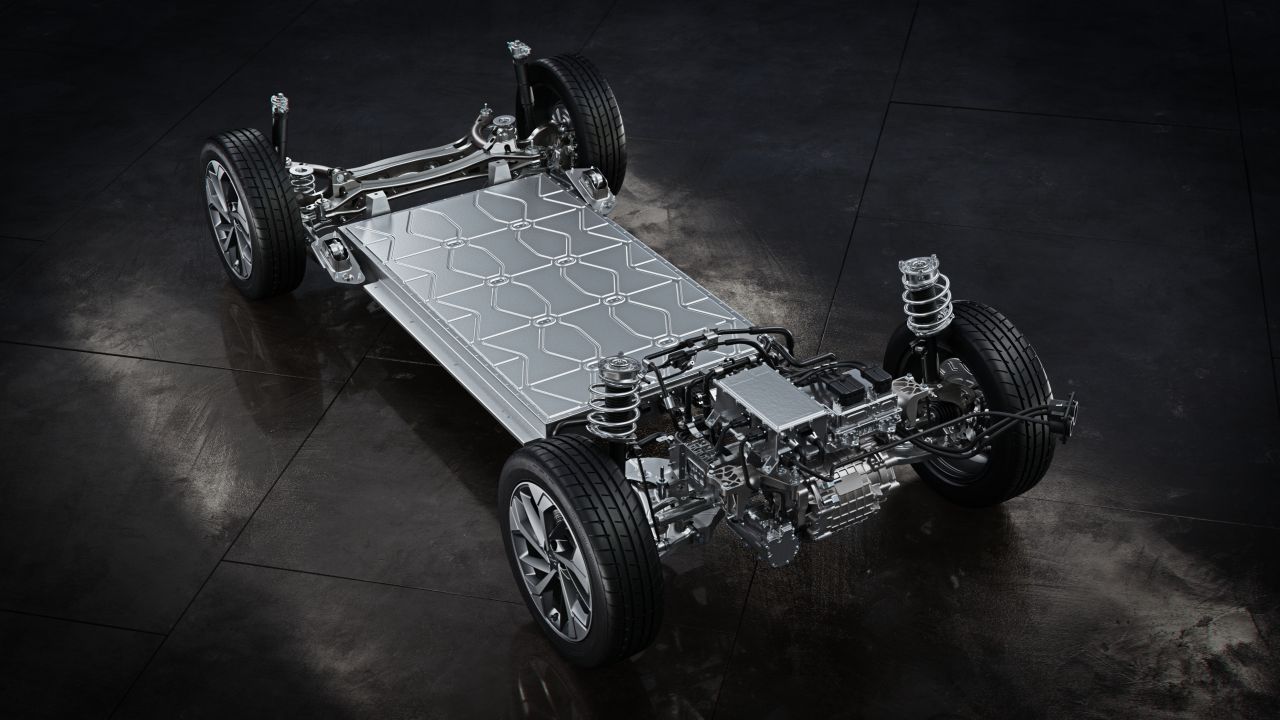

The MAS (More Adaptable Structure) platform developed by Aiways, a Shanghai-based provider of customized mobility solutions, combines innovative technical solutions to create an intelligent architecture. For example, the body-in-white of the Aiways U5 SUV is made of 52 percent lightweight and corrosion-resistant aluminum and 48 percent specially alloyed high-strength steels.

MAS platform with intelligent aluminum-steel lightweight material mix

These are up to four times stronger than conventional special steels used in vehicle construction and ensure maximum safety. Innovative bonding and joining techniques in the body-in-white mean that the torsional stiffness of the aluminum substructure is 50 percent higher than with conventional construction methods. In addition to the Aiways U5 SUV, the U6 SUV-Coupé, which will soon be making its debut, and other models will also be based on this flexibly adaptable platform.

Patented sandwich structure of the high-voltage battery with intelligent thermal management

The MAS platform is also distinguished by its pioneering battery architecture. A patented sandwich structure not only ensures high crash safety for the 24 battery modules supplied by CATL, but also enables the use of an intelligent thermal management system to increase the efficiency of the high-voltage system. A multilayer insulating protective layer separates the battery modules in the dry zone from the cooling plates in the wet zone. This not only increases efficiency but also the operational reliability of the lithium-ion battery, which can be optimally cooled or preheated thanks to the sandwich structure. The thermal management system of the Aiways U5 SUV thus enables operation at the best point of the 63 kWh pack at all times, which helps to ensure a long service life. Aiways guarantees 75 percent residual battery capacity even after eight years of operation. With a power density of 172 watt-hours per kilogram, the high-voltage battery is also among the top performers in its segment.

High-speed permanent magnet synchronous electric motor saves weight and installation space

The engineers at the Aiways Research Center in Jiading also used lightweight designs for the drive system. The permanent magnet synchronous electric motor developed in-house, for example, rotates at 16,000 rpm, about 25 percent higher than the machines used by competitors. It can therefore be smaller and lighter. The drive unit consisting of electric motor, gearbox and inverter generates an advantage of a good 15 percent less installation space and weight and can also be used in a modular fashion. In addition to installation in the front of the vehicle and front-wheel drive with 150kW and 310Nm as in the Aiways U5 SUV, it is also possible to configure a rear-wheel drive and an all-wheel drive based on the MAS platform.

Best-in-class curb weight ensures high efficiency and low wear and tear

The intelligent aluminum-steel lightweight material mix, combined with the innovative sandwich battery and compact electric drive unit, ensures an unladen weight of just 1,720 kg in the standard version of the Aiways U5 SUV. This not only makes it up to 350kg lighter than competing models in its class, it is actually lighter than many conventionally powered mid-size SUVs. The low weight not only ensures low energy consumption, but also high economy thanks to reduced wear. Components such as brakes, tires or chassis bearings are subjected to less stress than in other vehicles in its class due to the relatively light curb weight.

100,000km service interval ensures low maintenance costs

Another advantage of the lightweight concept and the correspondingly low stress on components is the ability to offer a long service interval. The Aiways U5 SUV only needs to be serviced by an Aiways service partner every 100,000 kilometers or 36 months, whichever comes first. As part of the mandatory vehicle maintenance, the brake fluid and coolant of the high-voltage battery, the oil level in the reduction gear of the powertrain are checked, topped up or changed, and the battery of the telematics box is replaced. All other maintenance is performed as needed. The 100,000km service interval thus not only enables very low operating and maintenance costs, it also saves many raw materials in the form of operating supplies or wear parts compared to conventional vehicles.

Management Quotes:

Dr. Alexander Klose, Executive Vice President of Overseas Operations at Aiways: “With the MAS platform, our engineers have created a real milestone. The technology used for the body, chassis, battery pack and drive unit are groundbreaking and unique in the class of the U5 SUV. During development, it was particularly important to us that the customer ultimately buys a vehicle that is not only sustainable and electric, but also scores with low maintenance costs. Particularly in view of current energy costs, it is becoming increasingly important to take a leading role in this area. Thanks to the high flexibility of the new platform, we are also very well positioned for future models, such as the upcoming U6 SUV-Coupé.”

Mikael Nilsen, Head of After Sales Aiways Overseas: “The operating and maintenance costs of a battery-electric vehicle such as our Aiways U5 SUV have come into the focus of customers, not least with the sharp rise in energy costs. Many studies already attest to cost advantages of up to 20 percent for electric cars over conventional vehicles in almost all application scenarios. With our intelligent lightweight platform and the resulting long service interval of 100,000km, we can score additional points and achieve cost advantages for our customers.”